Project description

A new concept for the economic use of tidal power

Recently, some prototype plants have been built for the use of tidal power for electricity generation. Most of these plants operate on the principle of conventional wind turbines. However, most of these plants so far can only use one flow direction and are very expensive to manufacture and maintain. Costs of over 5 million Euros for a 300 KW turbine have been published by the manufacturers. These plants are only cost-covering with immense subsidies.

In general, almost all known tidal power installations combine astronomical manufacturing costs with landscape disfigurement and hazards to marine life and shipping.

This turbine is currently probably the only one in the world that can use both the upstream and downstream tidal currents completely automatically without external control and generate electricity practically without interruption except for the change in tide (see animation below).

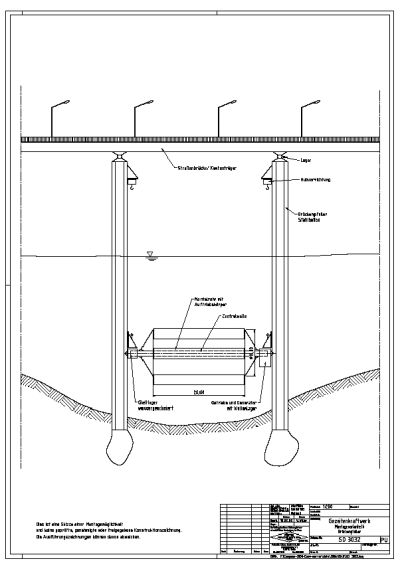

Unlike all other concepts, it disappears completely below the water surface and can be easily installed at a depth of more than 15 meters below the low water level, e.g. by simply lowering and anchoring it to the seabed, and thus, also unlike all other systems, it does not pose any obstacle to shipping.

The following diagrams give a visual impression of this completely new type of power plant:

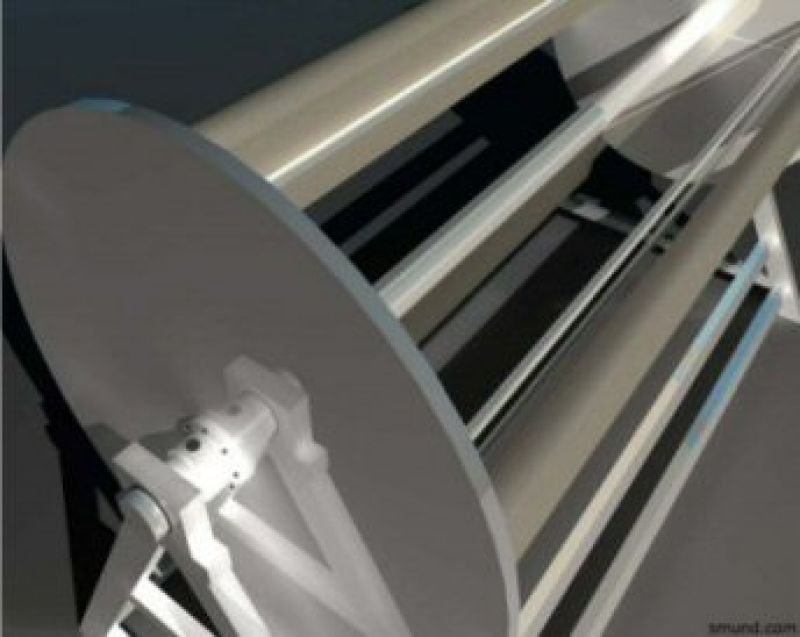

Between two circular plates, each eight meters in diameter, mounted on supports, is the efficiency-optimized number of five drop-profiled blades, each 20 meters long. These size specifications apply to the first prototype, which was calculated by the Pfleiderer Institute for Turbomachinery at the Technical University of Braunschweig in several study projects.

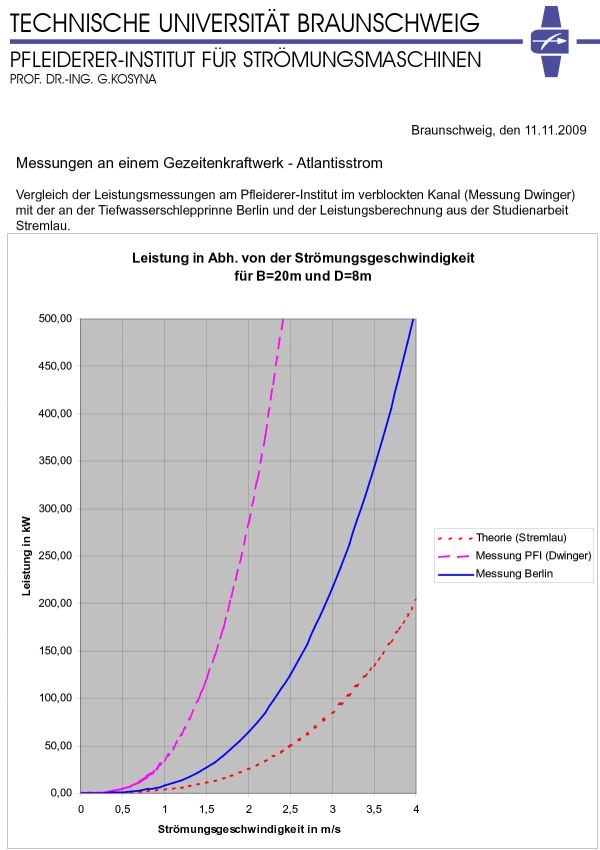

When installed at a barrage (e.g. Eider barrage or the culverts of the Delta barrage in the Netherlands), Atlantisstrom will deliver significantly more current than in the open sea due to the blockage situation. See in the diagram below: "Measurement PFI TU Braunschweig Dwinger".

Comparison of the performance measurements at the Pfleiderer Institute in the blocked channel (measurement Dwinger) with that at the deep-water towing channel Berlin and the performance calculation from the student research project Stremlau.

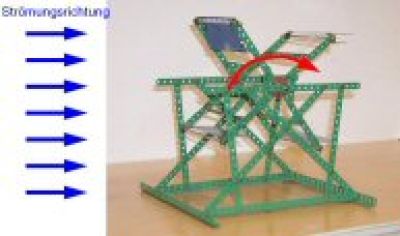

The turbine owes its ability to rotate - completely under water - to a completely new, patented folding mechanism of the blades, which causes an energy surplus at the pressure surfaces of the blades on the flow side, which starts the turbine and keeps it moving. The electric current is generated by a generator attached to the side plates.

The plant can be erected inexpensively from conventional shipbuilding steel. Transport to the installation site does not require special vehicles, but can be carried out, for example, as deck cargo of general cargo vessels. Two barges are required for assembly; between these pontoons, the plant can be lowered to the seabed by assembly cranes.

Two-point mounting of the turbine makes it possible to secure it stably and permanently in fjords without major foundation work, e.g. on two opposite rock faces by means of ropes (see above). In addition, the system can be fixed in softer seabeds by means of driven-in steel tubes.

The concept presented aims to generate energy from the inexhaustible source of tides at a price that is competitive even without subsidies. The project is therefore not only technically attractive, it also offers great economic potential in a growth market that has yet to be developed.

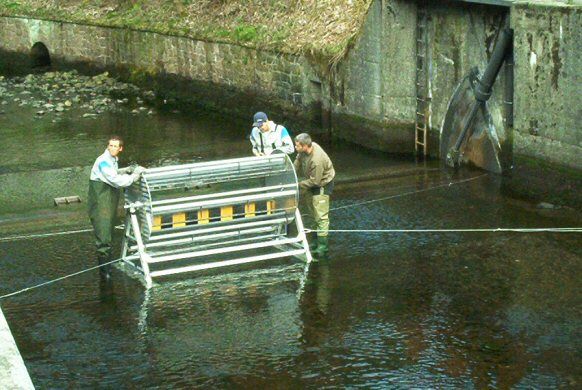

In cooperation with the Technical University of Braunschweig and the Harzwasserwerke GmbH, a 1:10 scaled-down demonstrator of the prototype was built by VW-Coaching GmbH and has already been tested several times in the outlet of the Okertalsperre.

On 09.06.2004 a public presentation of the demonstrator took place at 14:30 o'clock in front of the Okerkraftwerk Romkehalle at the foot of the Okertalsperre near Bad Harzburg.

We would like to express our sincere thanks to VW-Coaching GmbH, the Pfleiderer Institute for Fluid Machinery at the Technical University of Braunschweig and the public relations department of the Harzwasserwerke for their dedicated and valuable support.

After successful testing of our prototype in Tönning on the Eider River on August 4, 2004, the test was repeated on August 25, 2004, at the Eider Barrage and examined in terms of measurement technology by employees of the TU Braunschweig from the Pfleiderer Institute for Fluid Machinery. At the same time, a television team from MDR filmed this experiment for the program "Einfach Genial". The program was broadcast on MDR on September 21, 2004 at 7:50 p.m., on RBB on September 27, 2004 at 4:35 p.m., and on NDR on September 29, 2004 at 6:15 p.m. This edition deals with topics of renewable energy.

The company Köster GmbH & Co. KG Maschinenfabrik und Gießerei Heide/Holstein has prepared a detailed cost estimate for the construction of a tidal power plant in the 300 kilowatt class calculated by the TU Braunschweig.

In 2002, a computer-aided study was carried out at the Pfleiderer Institute for Turbomachinery at the TU Braunschweig to calculate the performance of an Atlantisstrom tidal power plant with a diameter of 8 meters and a length of 20 meters.

The results are shown in the curve "Theory (Stremlau)".

In December 2008, the power of an Atlantisstrom prototype with 1m diameter and 1m length was measured in a flow channel at the TU Braunschweig and extrapolated to an Atlantisstrom tidal power plant with the same size as in the Stremlau paper (20m length 8m diameter).

The results form the curve "Measurement PFI (Dwinger)".

In August 2009, the prototype mentioned above was tested and measured for its power output in the 8 meter wide and 4 meter deep towing channel at the TU Berlin. The results were also extrapolated to a tidal power plant with 20 m length and 8 m diameter.

They form the curve "Measurement Berlin".

If one compares the 3 curves in the diagram one recognizes that according to the theoretical work "Stremlau", with a 20 m long and 8 m diameter tidal power plant at a current speed of 2 m/sec only about 25 kW would be produced.

The measurement in the Berlin drag channel resulted in 70 k/W power at the same flow velocity (2m/sec) and the same extrapolation of the measurement data to a rotor with 8 meters diameter and 20 meters length.

The measurement in the flow channel of the TU Braunschweig resulted in an extrapolated power of far more than 200 k/W at the above mentioned flow velocities (2 m/sec.) and a rotor of the above mentioned size.

These above mentioned measurements thus show that the powers are strongly dependent on the blockage* of the flow by the tidal power plant.

In case of strong blockage, as in the flow channel of the TU Braunschweig, a power of a tidal power plant with 8 meters diameter and 20 meters length, as in the "Measurement PFI (Dwinger)" would be expected.

With low blockage of a flow as in the measurement in the drag channel Berlin, a power as in the "Measurement Berlin" would be expected.

Conclusion:

The extrapolation of the flow channel measurements proves that our tidal power plant produces several times the power previously assumed and thus has by far the best price-performance ratio of all tidal power plants.

*Blockage: If the tidal power plant is positioned in such a way that only a small amount of water can flow past the power plant on the left and right, this is referred to as a strong blockage, e.g. under a bridge. If the tidal power plant is placed in a wide fjord instead, a lot of water can flow past the tidal power plant on the left and right side and one speaks of a low blockage.