Construction failure of the Atlantisstrom prototype and end of the project on the Faroe Islands

Why did we choose the Faroe Islands to build the 1st Atlantisstrom prototype?

The Faroe Islands are not part of the EU, but belong only to the Danish Kingdom.

They can therefore permit tidal power plants according to their own rules without having to take EU regulations into account.

Approval for the construction of the tidal power plant by all the relevant authorities was obtained within a few weeks.

The main problem on the Faroe Islands is the smaller population (about 50,000 inhabitants), which meant, for example, that there was only one large steel construction company capable of producing the Atlantisstrom prototype.

This metal construction company knew that they were without competition in our project, since no other company in the Faroe Islands was building this prototype.

Therefore, from the beginning, the company refused to give any guarantees for the construction, installation and operation of the Atlantisstrom prototype.

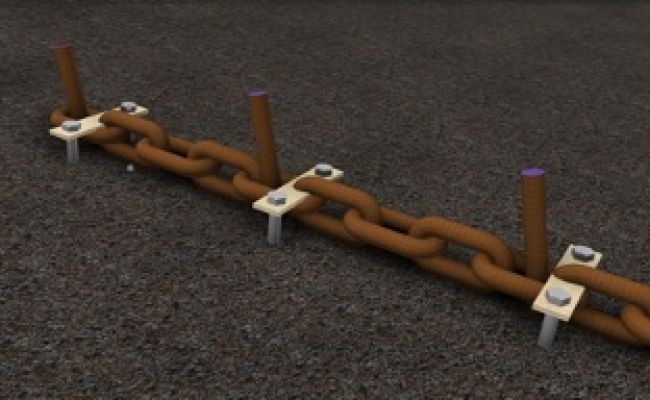

By agreement, the Atlantisstrom prototype was to be anchored in the rocks of the shore area by means of steel rods. The ends of the anchoring chains were to be placed over the steel rods drilled into the rock and bolted to them from above. (see drawing 1 below)

However, the steel construction company omitted the agreed bolting (see silver bolting in drawing below) of the anchor chains to the steel rods that were fixed in the bank rock.

Therefore, during a storm on 27.04.2013 at the higher swell, the chains could loosen from the steel bars. (see picture 2 and 3)

The tidal power plant drifted after losing its mooring and was severely damaged. Salvage and repair of the Atlantisstrom prototype was very costly. (receipts available upon request)

This damage to the prototype occurred only because the contracted structural steel company, contrary to agreement, failed to bolt the anchor chains to the steel bars in the shore rock.

After the prototype was restored and anchored again, this time as agreed, the anchoring held for over a year without any problems. (see picture 4 to 7)

Vereinbarte Verschraubung der Ankerketten mit den Stahlstäben die erst bei der 2. Installation ausgeführt wurde.

Verbogene Stahlstäbe im Fels nach dem Abspringen der Ankerketten durch nicht angebrachte Verschraubungen.

Atlantis Current tidal power plant still without blades after recovery. (blades lie on the seabed)

Atlantisstrom back at the construction yard.

Steel rods for anchoring in the rock, with subsequently correctly installed bolting of the anchor chains, after the faulty first installation with the anchor chains coming off the steel rods.

Correctly bolted anchor chain with the steel bars in the shore area after the 2nd installation.

2. second construction error of the executing company in the bolting of the components.

Incorrect and too weak bolting of load-bearing components

The Atlantisstrom prototype was severely damaged after it broke away from its incorrectly designed mooring, in April 2013, and had to be recovered at great expense.

The salvaged parts were reassembled at the shipyard.

By early November 2013, the prototype, this time properly anchored and bolted in place, was at its installation site and connected by submarine cable to the onshore inverter station (see full-size construction, part 5 Connection to the power grid).

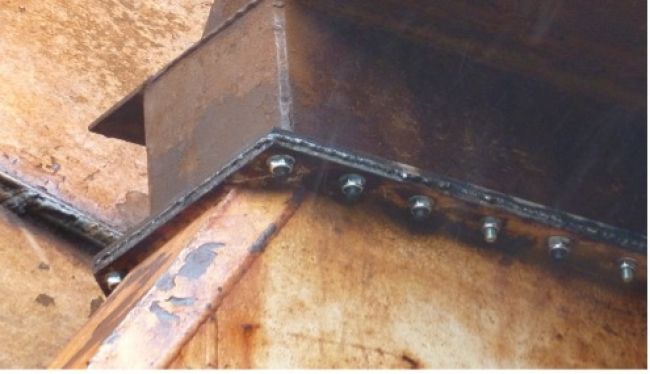

On 23.11.2013 the screws , which connect the axle bearing with the side part on the opposite side to the generator, gave way.

This caused the axle with the blades on that side to detach from the Atlantisstrom prototype.

Again, all parts had to be salvaged and laboriously bolted and welded together correctly this time. (see picture 8)

-

load-bearing steel elements were connected to the prototype with screws that were much too thin

-

you can see that the used screws have much smaller diameter than the hole in the steel plate

-

thicker screws were foreseen in the contract, which were able to securely hold the components together

-

due to a serious mistake of the executing company much thinner bolts were used, which of course broke under the load in the flow (see also photos below)

Atlantisstrom salvage after 2nd serious construction failure

After the 2nd construction botch, all parts were recovered and screwed together again, this time with the correct screws (see photo below).

The screw connection held reliably this time, throughout the subsequent anchoring period.

3. third party construction error of the executing company.

Vertragswidrige und falsche Ausführung der Rotorblätter.

It attached far too thin steel plates to the rotor blades, which were only spot-welded and filled with concrete on the inside to fool us into thinking they had sufficient steel weight and strength.

The fabrication and anchoring of the Atlantisstrom prototype was originally agreed with the contractor for €1,000,000. By the time the system was erected and installed for the third time, we had been invoiced €2,300,000 by the executing company.

The number, shape and weight of the rotor blades were calculated in several student projects at the Technical University of Braunschweig and tested and optimized in practice in the flow channel of the Technical University of Braunschweig and in the towing channel of the Free University of Berlin. (see above) It is necessary for the optimum energy yield that the flaps have the correct weight in addition to the required stability. The flaps have the lowest resistance during the recirculating movement (see animation), if their weight corresponds to that of the water. This characteristic of the flaps was agreed with the manufacturer. The necessary weight of the flaps was to be achieved by sufficient thickness of the steel plate and foaming of the cavity of the flaps.

The executing steel construction company did not achieve the necessary weight by using steel plates of sufficient thickness, but they partially filled the inside of the flaps with concrete to feign sufficient steel plate thickness. So, when checking the weight of the flaps and their construction, we were deceived. (see photos) The flaps were covered with steel plates that were much too thin and these were welded, even only selectively, to the stabilizing ribs and side panels. (see photos below)

When the turbine was anchored, installed and connected to the power grid for the third time for the test run, the cladding plates of the rotor blades came loose after only a few hours. (see video recording at construction in original size 4th part) Since we could not get any warranty for the prototype from the manufacturer, it was possible for him, even this previously difficult for us to verify construction error, to carry out without that we could have sued afterwards with prospects of success, against the company.

Concrete weight protrudes from the inside of the flap

Broken spot weld, i.e. no continuous welding of the internal ribs to the steel plates, which are much too thin.

4. end of the project in the Faroe Islands

The executing company refused any free rectification or repair of the rotor blades of the prototype.

Since this company was the only steel construction company on the Faroe Islands and we had lost all confidence in this company after the 3 serious construction errors, we had no choice but to stop the construction of the Atlantisstrom prototype there.